Tensioning

Tensioned belts make quality prints

The most common method of moving the parts of a 3d printer throughout the build volume is to have a series of belts connecting the moving part to a stepper motor. While there are other methods, they are either too expensive or not accurate enough to use in a printer. There are different levels of quality and materials that belts can be made of, but every belt driven printer will need to be re-tensioned as time passes. The constant pulling back and forth movement of the printer parts will stretch the belt out over time. This is caused by the stepper motors having to overcome the inertia of the printer head or the print bed.

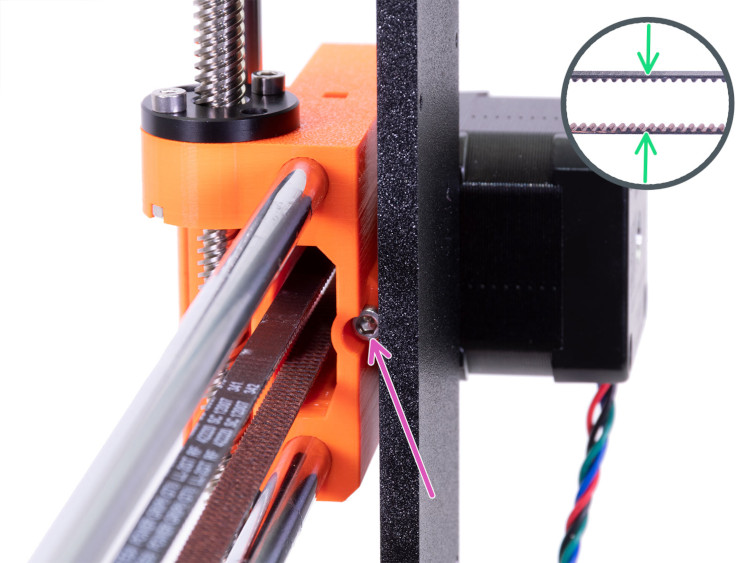

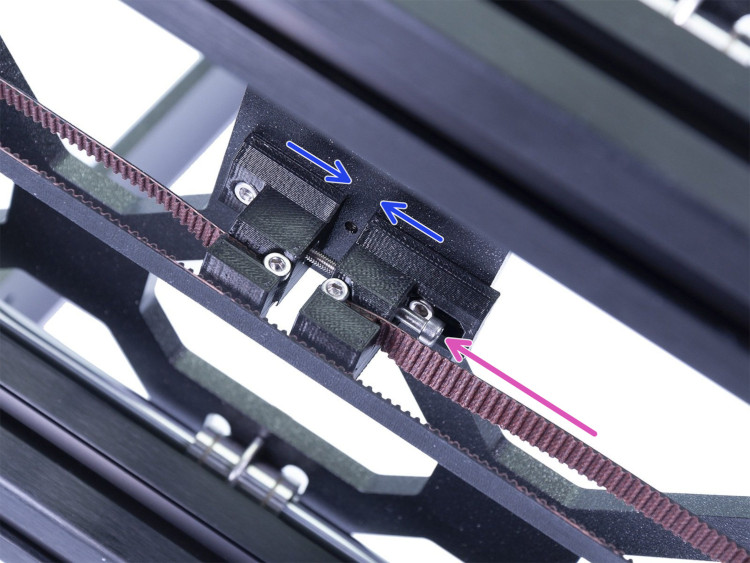

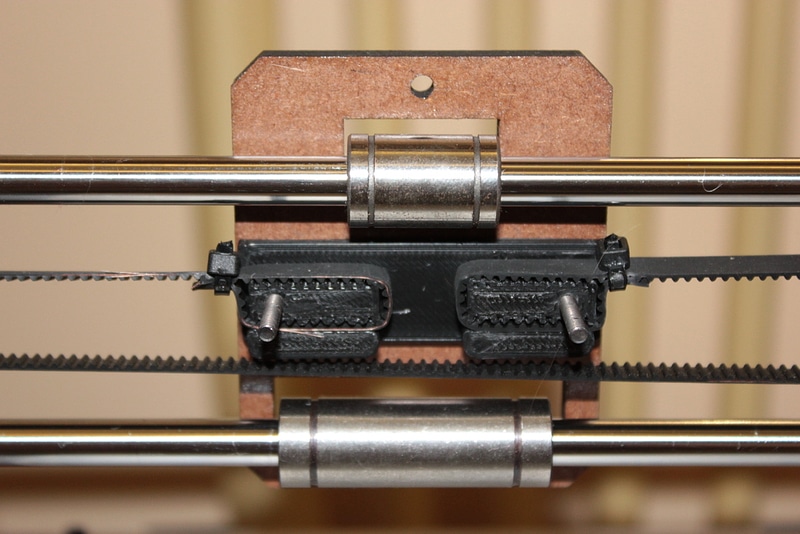

There are multiple configurations for belt driven 3d printers. The most common orientation is called a Cartesian printer, more commonly known as a bed slinger. This consists of a build surface often called the bed that moves back and forth, combined with an extruder that travels perpendicular to the path of the bed mounted on an arm that raises as each layer is finished. Tensioning the belts is a very easy process, but it differs from printer to printer. Prusa makes the process even easier, providing a web app that helps you make sure the belt is not over or under tensioned. To adjust the tension on a Prusa i3Mk4, there is a small bolt on the left end of the print head arm used to pivot the stepper motor which increases or decreases the belt. The Bed has a similar process, but instead of pivoting the motor it moves the mounting location.